Veejay Plastic Injection Molding Company has a 40 year proven track record as a leading American supplier of precision custom plastic injection molded parts. Our machines and tooling are highly customizable to meet your exacting custom plastic injection molding requirements, pertaining to part shape, size, material, and volume.

Veejay Plastic puts its cutting-edge engineering ingenuity to good use on your project. We specialize in micro molding, over molding, insert molding, miniature molding and custom micro injection molding.

We are one of the few American firms proficient in the use of highly engineered new-age materials such as PEEK, ULTEM, Vectra, ZENITE (liquid crystal polymer). Besides these, we also carry capabilities to honor part requirements with conventional thermoplastic resins.

With a proven track record of working with both private and government entities, Veejay Plastic has built a rich and varied portfolio of products and services in custom injection molding.

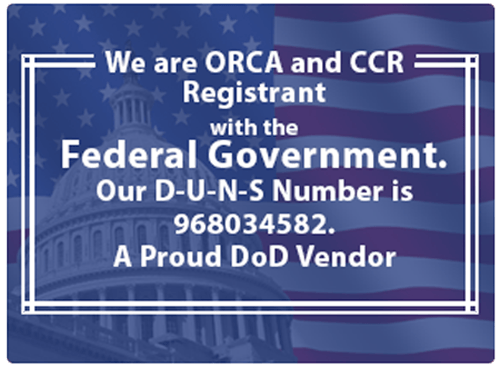

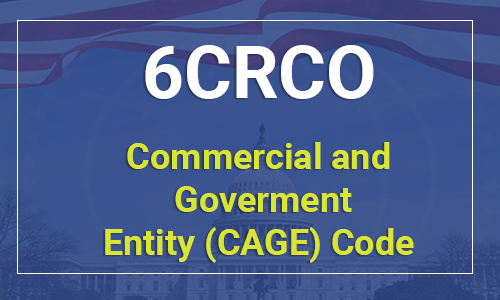

We are a CCR and ORCA registrant with the Federal Government. Thus, we can partner with you as a vendor for government projects, and we can work with commercial and industrial vendors.

Though we are based in Illinois, Veejay Plastic customarily works with OEMs, suppliers, and other industries all across the United States and Canada. We offer custom plastic injection molding services such as:

We are proud to state that Veejay Plastic Injection Molding Company recently successfully accomplished a pioneering milestone in the micro-molding industry. We have successfully molded an intricately designed part that weighs 1 milligram (0.001 gram). This micro molded part can only be seen through a high power microscope.

Veejay Plastic used highly engineered thermoplastic resin molded at ultra high temperature as the molding material. This, and other similar products that we are working on, are poised to bring about better efficiencies in groundbreaking applications of the twenty first century.

To learn more about how we can assist you with our Custom Plastic Injection Molding services, please speak with a trained Veejay Plastic representative.

Veejay Plastic Injection Molding Company has earned a reputation as a reliable and efficient plastic molding company. We provide high quality plastic products and services for companies throughout the United States and Canada. We offer turnkey operations to drive down the cost for industries such as electronic, construction, packaging, consumer, automotive, and aerospace, to name a few.

We provide a wide variety of services for our clientele. Services such as micro molding, insert molding, and miniature injection molding. We are equipped with as low as 17 tons, and as high as 220 tons presses with single to multiple cavity operations. In addition, we routinely mold extra high-heat resins modified with carbon fiber, glass fiber, glass beads, and mineral additives, along with thermal plastic resins such as ABS, Nylon, polycarbonate, PET, Liquid Crystal Polymers, PEEK, ULTEM, and Vectra to name a few.

We take great pride in not only the quality of our products, but also in our public relations with a particular emphasis on customer satisfaction. We recognize that the quality of our products are integral to the success of our customers’ businesses, and therefore strive to maintain a strict level of professionalism and quality control while at the same time, making efforts to improve our operations to fit the needs of our clientele.

Plastic Injection Molding Capabilities |

|

| Industry Focus | Aerospace , Automotive , Communication , Construction , Electrical , Electronic , Optical |

| Material | ABS , Acetyl , Acrylic , Copolymer Polypropylene , HDPE/LDPE , Nylon , PEEK , Vectra , PET , Polycarbonate , Polyester , Polypropylene , Polystyrene , Polyurethane , ULTEM , Liquid Crystal Polymers |

| Product Capabilities | Medium-sized parts , Micro parts , Miniature parts , Small-sized parts |

| Services | Insert Molding , Over Molding , Mold Making , Kanban Program , Inventory Managed Shipment |

| Production Volume | Low Volume , Small Runs , High Volume , Large Runs , Sample Runs |

| File Formats | AutoCAD (DWG) , IGES , JPEG or JEPG , PDF , Solid Works (SLDPRT, SLDDRW, SLDDRT) |

| Shot Size | 5mg (min) – 450g (max) |

| Clamping Force | 17 tons (min) – 220 tons (max) |

| Number of Cavities | 1 cavity (min) – 16 cavities (max) |

| Tolerance (+/-) | Down to 0.0001 in. |